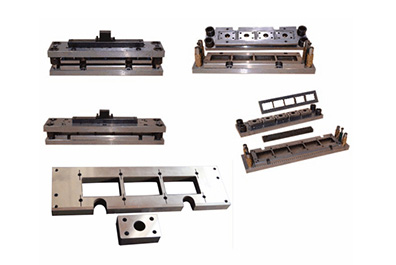

Long service life

Size is available to be customized

Apply to PVC, ABS, PET and PC cards

Use at most of the punching machines

Good embedded ability

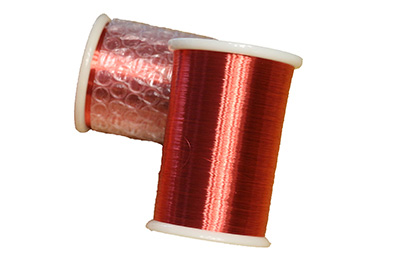

Match various coil manufacturing tech

Apply to L.F, H.F Inlay manufacturing

Apply to RFID card/tag manufacturing

Good pressurization

Reduced chip loss rate

Perfect heating conduction

Specially for RFID Inlay/Pre-laminated production

Better card surface quality

Glossy & matte types, customized size

Good thermal conductivity and pressurization

Commonly used in smart card manufacturing

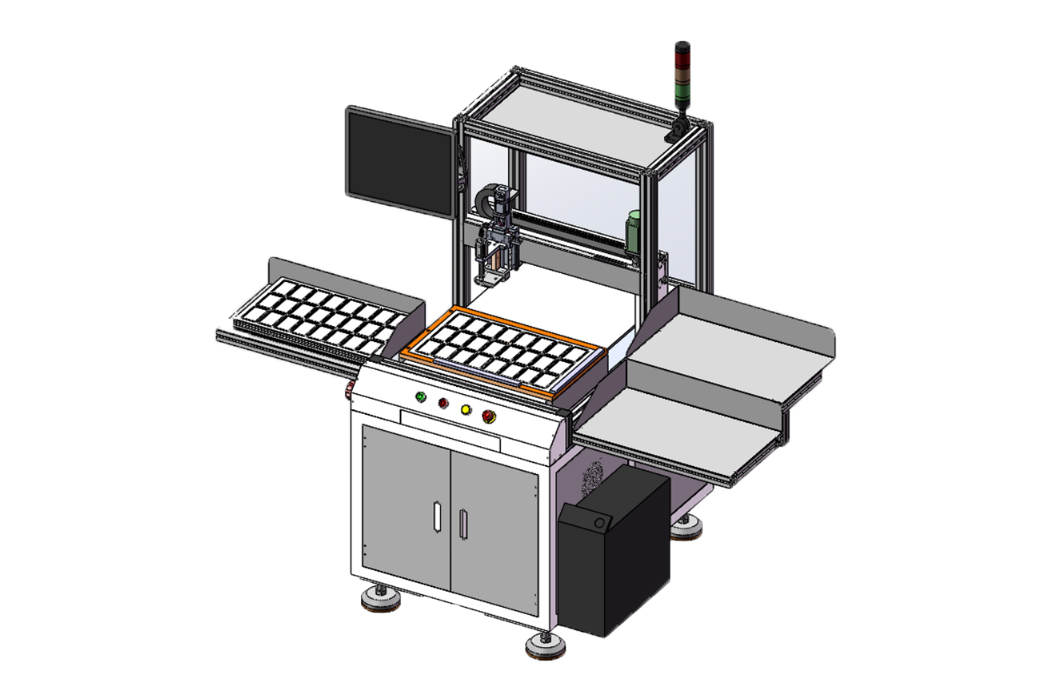

Online function and performance testing

Prelaminated Inlay for RFID Card

Inlays for Dual Interface Card

Inlay Sheet layout customized

Online function and performance testing

Prelaminated Inlay for RFID Card

Inlays for Dual Interface Card

Inlay Sheet layout customized

Online function and performance testing

Prelaminated Inlay for RFID Card

Inlays for Dual Interface Card

Inlay Sheet layout customized

Simple way to test HF Tag's performance

Support 13.56MHz (14443A/B, 15693 and NFC), also 8.2MHz EAS label etc

Results come automatically when test-item put on device

Test data can be input to PC via optional USB port and software

Chips for HF 14443A, B, 15693, NFC, Felica

Customized layout 2x5, 3x7, 3x8, 4x10, 7x8 etc

The best solution for inlay test in world market

Necessary Tools for Inlay & RFID Card Producer

First choice for RFID UHF products testing

Various size and parameters can be checked

Support single use or mass production

Cost effective and easy operation

Various size and parameters can be checked

Support single use or mass production

Cost effective and easy operation

products