RFID Inlay/Label Bending Tester RD-ZW2016A

Presentation:To testing the surface strength of composite PET with aluminium thin etching antenna

Advantage:Durable, Max. market share in China local brands

Application:RFID inlay, label manufacturer

Brochure Download:Down

- Overview

- Typical Client Needs

- Photo & Video

- Features

- Specification

- Why Buy It

- Reference & Feedback

- Service & Support

- FAQ

- Question & Advice

OVERVIEW

2. The running speed can be adjusted, and the speed range is 0-100 meter/min.

3. The running time and times of positive and negative inversion can be preset.

4. The operation of the drive shaft is divided into automatic and manual operation. The number of operating cycles can be preset manually, and the setting of positive and negative operation can be referred to automatically.

5. The rotation angle of the material can be adjusted by itself, and the adjustment range is 0-360 degrees.

6. Automatic shutdown after material disconnection;

7. Material tension is shown in digital display and the tension range is 0 ~ 20KG; Easy operation.

8. Anti-static rollers with different diameters can be provided according to customer's requirements.

9. Applicable to all material widths currently provided by domestic suppliers.

10. Material orientation can be set freely by one active axis and six driven axles.

Main Achievement

> Testing the surface strength of composite PET with aluminium thin etching antenna;

> The firm strength of the chip paste and the number of bending resistance of Inlay.

> Make Inlay into finished product by secondary packaging, and test bending test according to different environment.

It is mainly composed of timers, counters, sensors, speed-regulating motors, transmission rubber rollers, timing belt wheels and other components. The size of the equipment is L700*W600*H550mm and weight in around 75KG.

The tested material is driven by the speed-regulating motor to run automatically and repeatedly. The PLC timer sets the time of forward rotation and the time of reverse rotation respectively, and the touch screen displays the number of laps. The material is disconnected during operation, the sensor works, the equipment is suspended, the alarm indicator is on, the staff adjusts the material belt and presses the reset button, and the equipment continues to run.

The tensioning method is screw tensioning. After loading the material, tighten the tensioning screw to make the belt tension suitable and start the equipment to test and count, and display the tension number.

FEATURES

1. Set corotation and inversion time to run alternately.2. The running speed can be adjusted, and the speed range is 0-100 meter/min.

3. The running time and times of positive and negative inversion can be preset.

4. The operation of the drive shaft is divided into automatic and manual operation. The number of operating cycles can be preset manually, and the setting of positive and negative operation can be referred to automatically.

5. The rotation angle of the material can be adjusted by itself, and the adjustment range is 0-360 degrees.

6. Automatic shutdown after material disconnection;

7. Material tension is shown in digital display and the tension range is 0 ~ 20KG; Easy operation.

8. Anti-static rollers with different diameters can be provided according to customer's requirements.

9. Applicable to all material widths currently provided by domestic suppliers.

10. Material orientation can be set freely by one active axis and six driven axles.

Main Achievement

> Testing the surface strength of composite PET with aluminium thin etching antenna;

> The firm strength of the chip paste and the number of bending resistance of Inlay.

> Make Inlay into finished product by secondary packaging, and test bending test according to different environment.

1. Set corotation and inversion time to run alternately.

2. The running speed can be adjusted, and the speed range is 0-100 meter/min.

3. The running time and times of positive and negative inversion can be preset.

4. The operation of the drive shaft is divided into automatic and manual operation. The number of operating cycles can be preset manually, and the setting of positive and negative operation can be referred to automatically.

5. The rotation angle of the material can be adjusted by itself, and the adjustment range is 0-360 degrees.

6. Automatic shutdown after material disconnection;

7. Material tension is shown in digital display and the tension range is 0 ~ 20KG; Easy operation.

8. Anti-static rollers with different diameters can be provided according to customer's requirements.

9. Applicable to all material widths currently provided by domestic suppliers.

10. Material orientation can be set freely by one active axis and six driven axles.

2. The running speed can be adjusted, and the speed range is 0-100 meter/min.

3. The running time and times of positive and negative inversion can be preset.

4. The operation of the drive shaft is divided into automatic and manual operation. The number of operating cycles can be preset manually, and the setting of positive and negative operation can be referred to automatically.

5. The rotation angle of the material can be adjusted by itself, and the adjustment range is 0-360 degrees.

6. Automatic shutdown after material disconnection;

7. Material tension is shown in digital display and the tension range is 0 ~ 20KG; Easy operation.

8. Anti-static rollers with different diameters can be provided according to customer's requirements.

9. Applicable to all material widths currently provided by domestic suppliers.

10. Material orientation can be set freely by one active axis and six driven axles.

Those Might Attract You

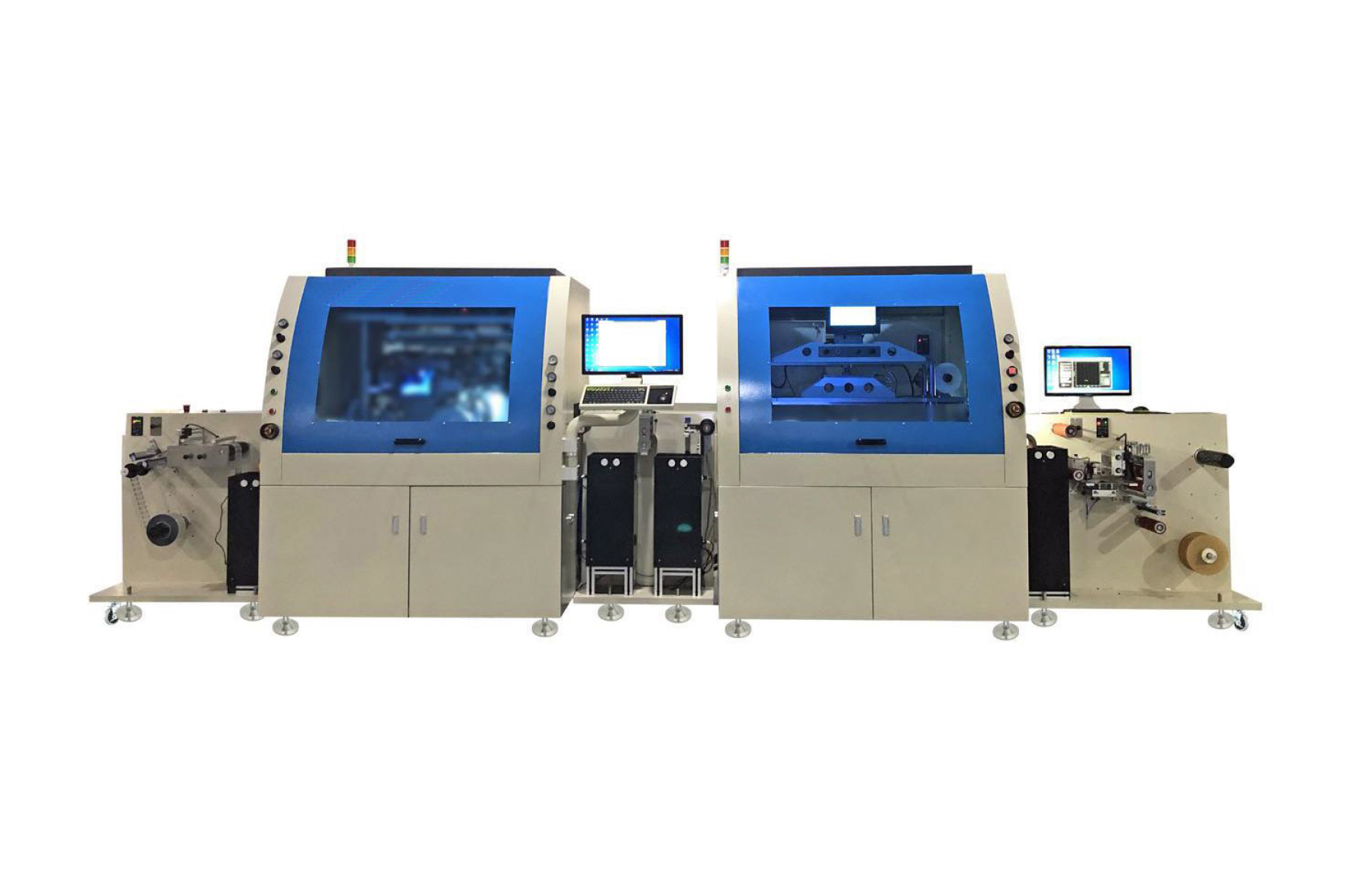

RFID Automatic Flip Chip System XJL-TTA20000

RFID Automatic Flip Chip System XJL-TTA20000

Top RFID Flip-chip system made in China.

Over 200 set used in the market

Available for all types of HF/UHF RFID inlay

Speed reach to 16,000UPH

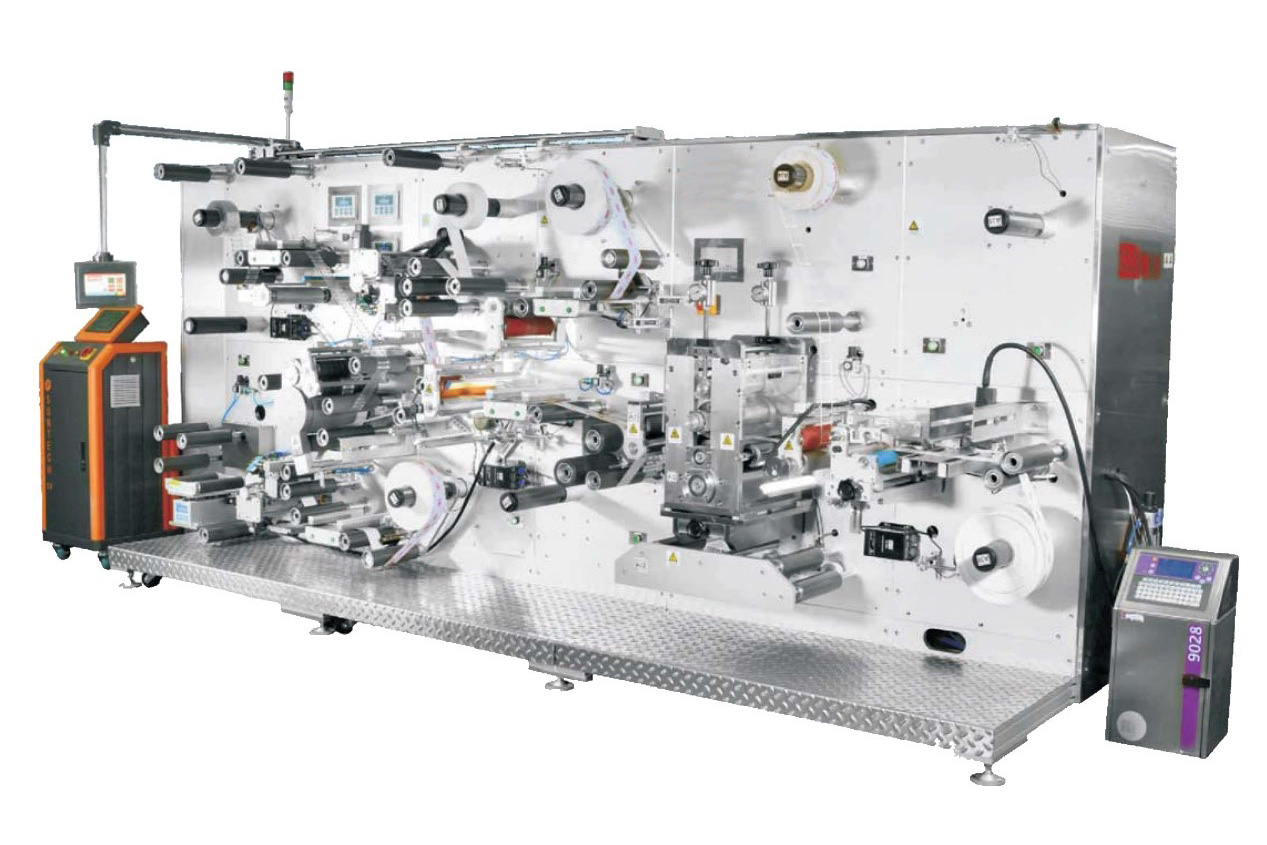

RFID Label Automatic Lamination Machine RFCL-822-RX

RFID Label Automatic Lamination Machine RFCL-822-RX

Multi layer and multi rows laminating

Speed may reach to 60 meters per minutes.

Laminationg accuracy is +/- 0.3mm

Available materials in RFID dry, wet inlay, etc

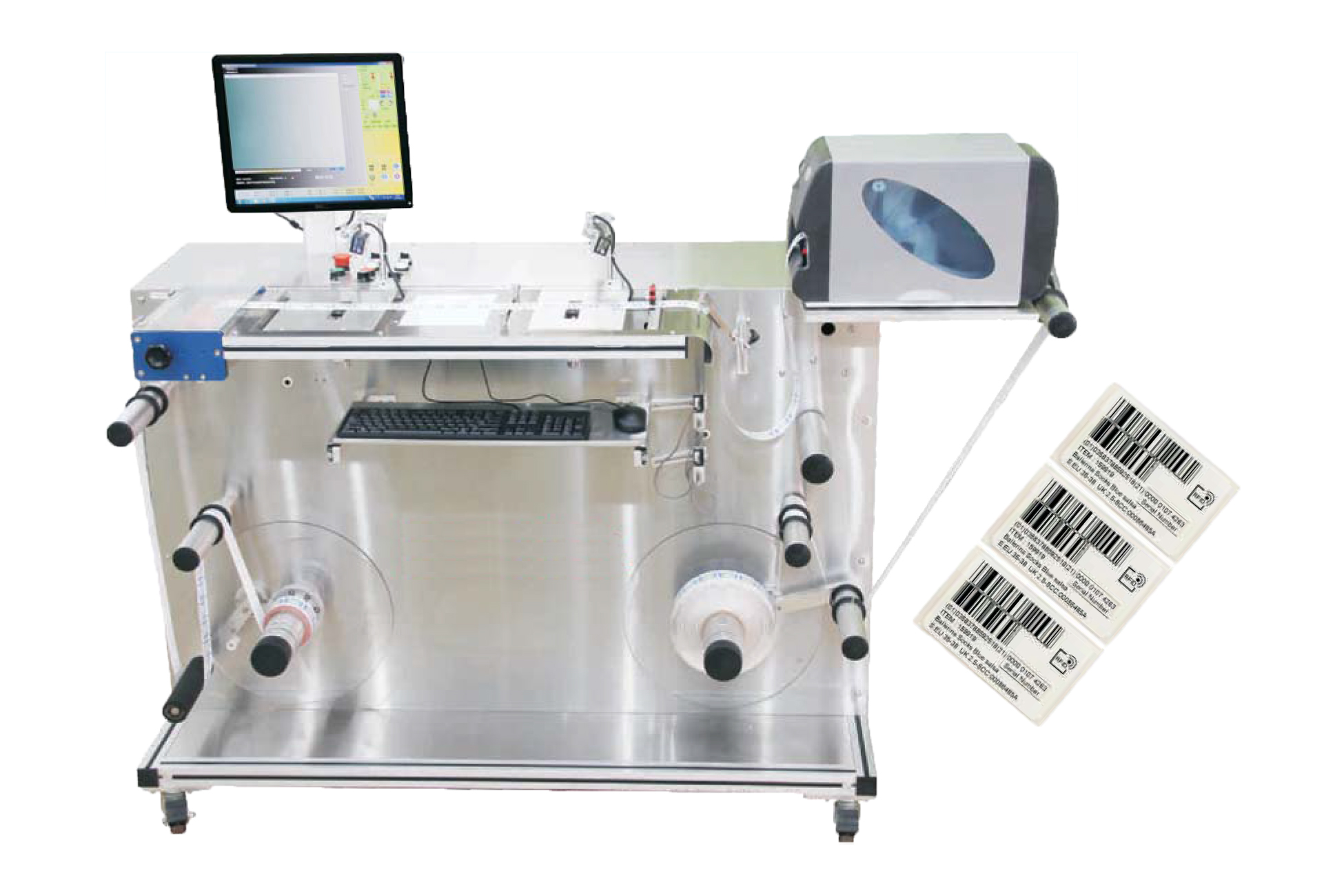

RFID Label Detecting & Encoding Machine RFES-1

RFID Label Detecting & Encoding Machine RFES-1

Available for reel labels encoding and detection

Support inkjet printing mark on product

Support EPC data encoding

Good performance on UHF or HF labels

300/600dpi HD Single Tag Printer

300/600dpi HD Single Tag Printer

Industrial thermal transfer printer for single tag

Support 300DPI and 600DPI

Support 1D bar code and 2D bar code.

Desktop type which is easy for operation

products