Presentation: Flexible,Fast and Printing solutions for labels and tags

Advantage: Wide product form applications. High speed and accurate CMYK printing for variable data

Application: Available for personalized color printing of various products such as clothing tags, cards, single labels, handicrafts, small commodities, etc.

Brochure Download:Down

- Overview

- Typical Client Needs

- Photo & Video

- Features

- Specification

- Why Buy It

- Reference & Feedback

- Service & Support

- FAQ

- Question & Advice

• The equipment has the functions of dust removal, double sheet detection, UV printing, pre-curing, main curing, and receiving and stacking counting.

• The movement mechanism is all servo motors, and the feeding is stable and accurate.

• The printing and curing are divided into two stages to reduce the mutual interference of the two modules on the belt

• Suitable for personalized color printing of various products such as clothing tags, cards, single labels, handicrafts, small commodities, etc.

SPECIFICATIONS

|

Printing Resolution |

• 600x600 (1200DPI) |

|

Printing Model |

• EPSON i3200-UI |

|

Printing Width |

• 34 mm (Scalable) |

|

Printing Speed |

• 30-60 m/min |

|

Feeding width |

• 25-300 mm |

|

Printing Content |

• Color, black and white, spot color |

|

Printing Color Group |

• CMYK |

|

Printing Material |

• Common labels, packaging materials (PET, PVC, coated paper, synthetic paper, writing paper, etc.) |

|

Overprint Accuracy |

• ±0.4 mm |

|

Ink Type |

• UV (Water-based optional) |

|

Curing Method |

• LED UV |

|

Substrate Thickness |

• 0.3-200 mm |

|

Printing Software |

• Support variable data/color RIP printing software |

|

Optional Function |

• Visual inspection and rejection, corona |

|

Total Power |

• 2KW |

|

Overall Size |

• 2430(L)x830(W)x1370(H) mm |

• The movement mechanism is all servo motors, and the feeding is stable and accurate.

• The printing and curing are divided into two stages to reduce the mutual interference of the two modules on the belt

• Suitable for personalized color printing of various products such as clothing tags, cards, single labels, handicrafts, small commodities, etc.

|

Printing Resolution |

• 600x600 (1200DPI) |

|

Printing Model |

• EPSON i3200-UI |

|

Printing Width |

• 34 mm (Scalable) |

|

Printing Speed |

• 30-60 m/min |

|

Feeding width |

• 25-300 mm |

|

Printing Content |

• Color, black and white, spot color |

|

Printing Color Group |

• CMYK |

|

Printing Material |

• Common labels, packaging materials (PET, PVC, coated paper, synthetic paper, writing paper, etc.) |

|

Overprint Accuracy |

• ±0.4 mm |

|

Ink Type |

• UV (Water-based optional) |

|

Curing Method |

• LED UV |

|

Substrate Thickness |

• 0.3-200 mm |

|

Printing Software |

• Support variable data/color RIP printing software |

|

Optional Function |

• Visual inspection and rejection, corona |

|

Total Power |

• 2KW |

|

Overall Size |

• 2430(L)x830(W)x1370(H) mm |

RSID Solutions is a professional machinery & ID solutions provider from Shanghai, a member of RealSmart Group Company founded in 2005. And Shanghai is a dynamic growing prosperity of the city, is China's largest commercial and financial center; is also the Western Pacific region important international port city. Its extensive contacts within and outside the transport, communications more developed, is attracting more and more attention to the eyes.

RSID Solutions aims to be a world class provider from China on cards manufacturing, application and ID solutions! Working with authorized top-level players, our global network will always be at your tailor-made service before & after sales, V.A.S as well.

Thanks for 15-years’ experience and numerous users’ trust, the most top players in card industry are using the machines & solutions which we highly recommended.

Whatever you are card & RFID manufacturer, personalization center or issuer, you will get reliable services & abundant resources here!

Strong Key Partners

Leading technical provider from China

• Secure ID & E-Passport

• Secure ID & E-Passport• Banking Machine

• E-Payment System

• Rail transit AFC

☆ More than 18 years professional service experience for global customers

Proven By Numerous Users

Professional Team

A Common Goal: To be a world class service provider for card/RFID making machines and ID solutions; to promote & accelerate the influence of machinery & ID Solutions made in China to global Smart Cards and RFID industry.

Abundant skills: Bachelor or above degree, mechanics or trade related major.

Smooth Information Exchange

Spirit & Enthusiasm: experienced young team with passion are ready for any challenge and opportunity. We will reply your inquiry within 24 hours and can afford you consultation for 24 hours of 7 days in the process of sale and after service by phone or mail. We will support you for advisory opinion in purchasing, explanation in various technical problems and reliable supply in technique support.

Values

• Customers are our employers, for whom we solve the problem and create more values abidingly.

• Employees are our best wealth, for whom we continuously widen the development platform and expand the space of survival.

• Partners are our business foundations, for whom we make more opportunities and benefit multi-win persistently.

• Society is our survival land to which we contribute by making efforts to improve day by day, and industry development as well.

Other Advantages

• Adequate Supply

• Attractive Price

• Customized Service

• More Than 10 Oversea Engineers Standby in 7*24 Hours

Europe:

North America:

South America:

Africa:

Oceania:

Special:

Services before Sales

- Reply your inquiry within 24 hours.

- Communication by email.

- Welcome you visiting our factory and final users in China.

- Help for VISA application and Invitation Letter issuing.

- We afford you consultation for 24 hours of 7 days in the process of sale and after service by phone or mail. We will support you for advisory opinion in purchasing, explanation in various technical problems and reliable supply in technique support.

Services on Purchasing

- Communication by email.

- Welcome you visiting our factory and final users in China.

- Help for VISA application and Invitation Letter issuing.

Services after Sales

- Online Support, 24 hours feedback once got the email

- Enough Spare Parts Preparation for you…

- Engineer to customer’s site for training & repairment

- Our equipments have 12 months for quality guarantee after sale. If the equipments do not work because of self cause, we will do free service and change the damaged spare parts.

- We will do life-long maintenance for all of our sold equipments. After quality guarantee period, if you can not maintain the equipments by self, we are under an obligation to go to work place and assist you to make maintenance. The cost of spare parts as well as expenses of traveling and man-hour of worker will be negotiated separately. Spare parts will be supported whether during guarantee period or not.

- After have finished maintenance, our service engineer will do training for the operators in plenty of time so that operators can be ensured to independently make operation, debugging and daily plant maintenance.

A: Yes. Our factory has engineers for installation and after-sales service. And we also have engineer who can speak English. We will offer the training on site. We will make the machine runs normal before going back.

Q: How long is the installation time?

A: It will take around 10 days for the installation, adjustment, training, running and we will stay there to make sure the machine works stable before we leave.

Q: Do you provide Remote Service?

A: Yes. We have applied this function on one customer from Taiwan by using Teamviewer. We can also apply this function in any customer who needs it.

Q: If there is an issue on the machine, how long do you response?

A: We will response within 24 hours when we know your problems by mail or phone, including the shipment of spare parts. If need on site support, we will leave for your site within 48 hours.

Q: How long is the guarantee period?

A: One year guarantee. Beside the easy-broken spare parts, other hardware parts would be provided freely within the guarantee period. Diagram would be provided also for you to change them. After the guarantee period, we still offer supports.

Q: Do you offer on-site service after installation?

A: Yes. If on-site service, you will be in charge of the accommodations and 150USD/day as service fee. We can offer the training or maintenance for on-site service.

Q: How about the Easy Broken Spare Part?

A: One set would be shipped with the machine together. Spare parts list would be provided with the user manual together. And you can order them at any time.

Q: What is the accuracy of the collation part?

A: The collation machine accuracy is ±0.1mm. We apply the sensors for the position and apply the servo system to do the collation which can ensure the accuracy.

Q: What is the welding device?

A: For collation part, apply 4 sets of ultrasonic welding devices. For the overlay parts, apply 4 heat welding devices.

Q: Could the machine apply 2 sheets feeding?

A: Yes. You may collate 2 sheets or 3 sheets. It is controlled by the HMI.

Q: Could the machine apply just one side overlay?

A: Yes. The machine can apply top overlay and bottom overlay together. It can also apply one side overlay: just the top overlay or bottom overlay.

Q: Could the machine apply the magstripe overlay and make sure the accuracy of the magstripe mounting?

A: Yes. The machine can apply a guiding system to detect the magstripe on the overlay, then place the overlay correctly on the sheets. It can make sure the accuracy.

Q: Can you test our sheets before we order it?

A: Yes. You can offer sample sheets for us. We will test them and then give you a report about your sheets. That is better way to make the machine as your requirements.

Q: How about the machine’s failure rate?

A: The machine has a very low failure rate. Besides the installation, generally only 1-2 times we will go to the customer place within 3 years. And which is mostly for the training of fresh men.

Q: How long is the changeover time?

A: In the first time of training, the technicians in your site will have around 3 layouts setting training so that you may have a clear mind about the principle. After that, it will take a very short time for the new layout to do the changeover.

Q: Do you offer FAT testing?

A: Yes. We offer the FAT testing for our clients. We can do test as your requirements. And during the testing, if you want to do any change for the machine, we can modify it in the factory.

Q: How about the machine working time?

A: The machine can work for 7*24 hours. The machine can be operated just by one operator.

Q: Do you accept the customized?

A: Yes. Machine can be customized. We can apply the machine to reach the clients’ requirements.

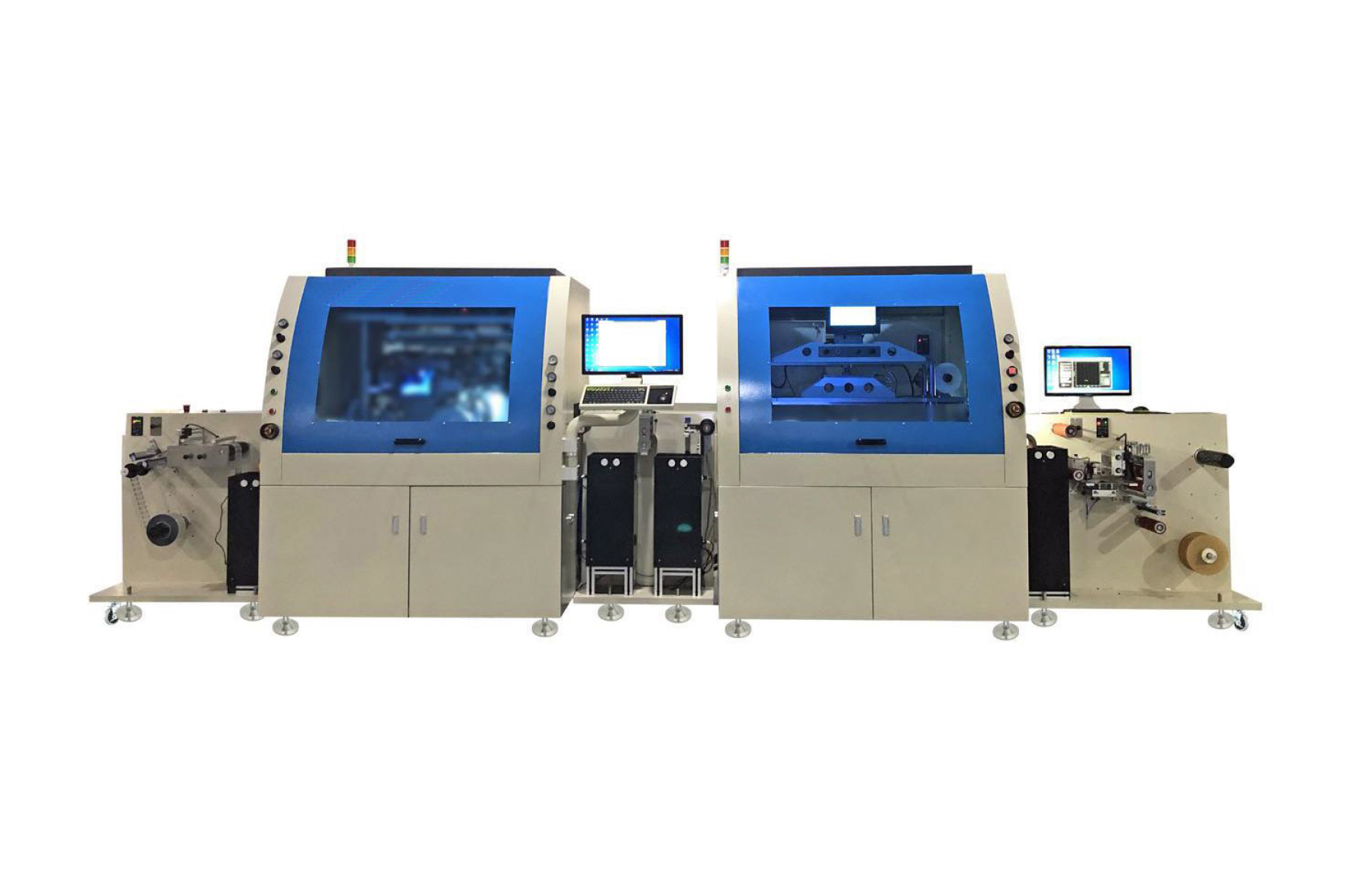

RFID Automatic Flip Chip System XJL-TTA20000

RFID Automatic Flip Chip System XJL-TTA20000

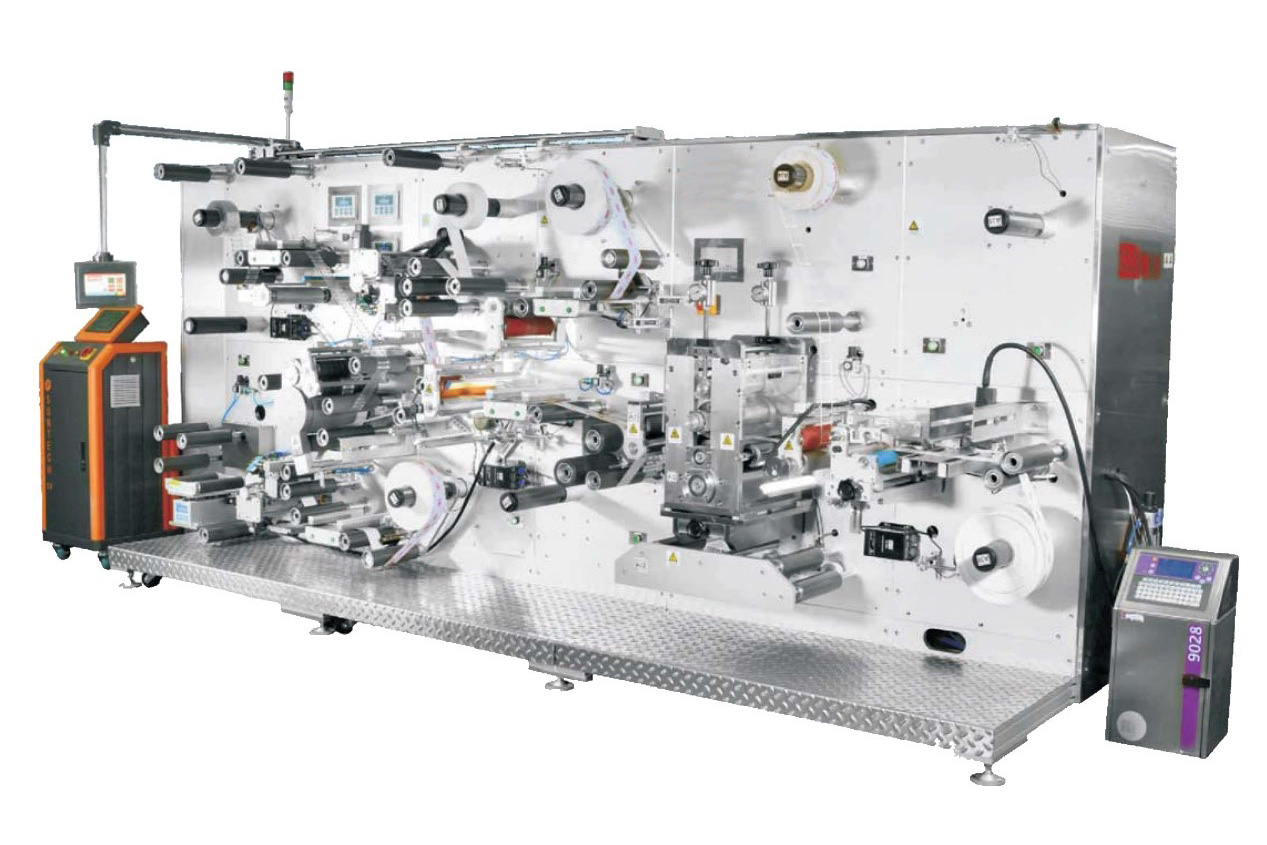

RFID Label Automatic Lamination Machine RFCL-822-RX

RFID Label Automatic Lamination Machine RFCL-822-RX

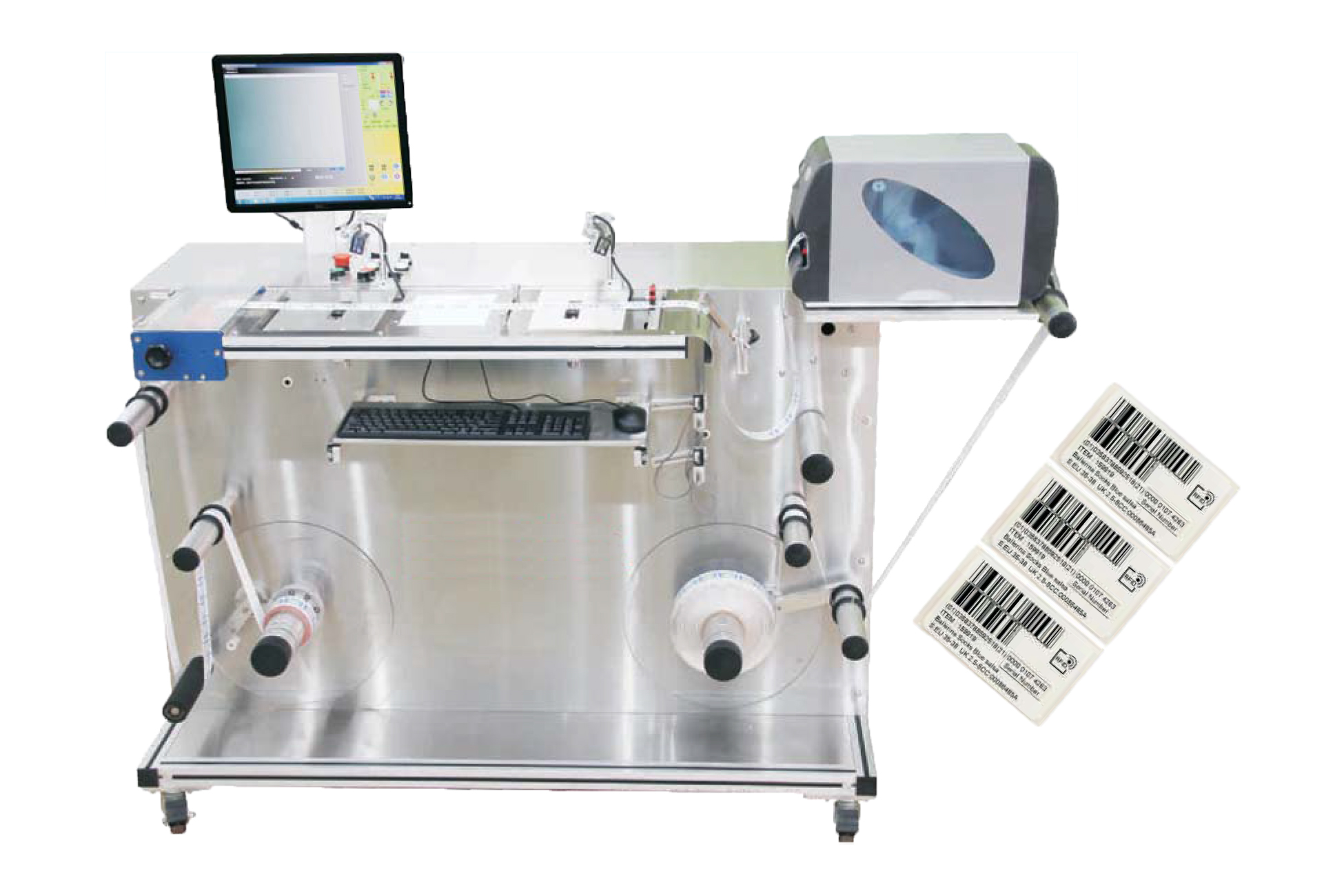

RFID Label Detecting & Encoding Machine RFES-1

RFID Label Detecting & Encoding Machine RFES-1

300/600dpi HD Single Tag Printer

300/600dpi HD Single Tag Printer