Presentation:High Speed RFID chip bonding for antenna

Advantage:Durable, Max. market share in China local brands

Application:RFID Inlay, Label Manufacturer

Brochure Download:Down

- Overview

- Typical Client Needs

- Photo & Video

- Features

- Specification

- Why Buy It

- Reference & Feedback

- Service & Support

- FAQ

- Question & Advice

OVERVIEW

Due to the booming of RFID technology, to meet the needs of different RFID inlay sample, we launch the new bonding machine which is widely used in lab for RFID inlay sample making

TECHNICAL CHARACTERISTIC

• Range in testing device: The adaptive experiment of electrician, electric parts and related materials in high/low temperature saving, transportation and using

• Testing condition: Environment temperature is +25℃. Relative humidity ≤85%. No exist samples in testing chamber.

• Testing way: GB/T 5170.2-1996 temperature testing device and GB/T 5170.5-1996 damp and hot testing device (Only damp/hot model)

• Temperature range: -70℃→+150℃ (Temperature fluctuate in ±0.5℃ and distribution accuracy in ±2.0℃)

• Humidity range: 20%~98%R.H (Humidity fluctuate in ±3%R.H and distribution accuracy in ±3.0%.) (Only damp/hot model)

• Heating up time: -70℃→+150℃ and 4.0℃/min in heating up time

• Heating down time: +150℃→ -70℃ and 1.0℃/min in heating down time

• Range in testing device: The adaptive experiment of electrician, electric parts and related materials in high/low temperature saving, transportation and using

• Testing condition: Environment temperature is +25℃. Relative humidity ≤85%. No exist samples in testing chamber.

• Testing way: GB/T 5170.2-1996 temperature testing device and GB/T 5170.5-1996 damp and hot testing device (Only damp/hot model)

• Temperature range: -70℃→+150℃ (Temperature fluctuate in ±0.5℃ and distribution accuracy in ±2.0℃)

• Humidity range: 20%~98%R.H (Humidity fluctuate in ±3%R.H and distribution accuracy in ±3.0%.) (Only damp/hot model)

• Heating up time: -70℃→+150℃ and 4.0℃/min in heating up time

• Heating down time: +150℃→ -70℃ and 1.0℃/min in heating down time

RSID Solutions is a professional machinery & ID solutions provider from Shanghai, a member of RealSmart Group Company founded in 2005. And Shanghai is a dynamic growing prosperity of the city, is China's largest commercial and financial center; is also the Western Pacific region important international port city. Its extensive contacts within and outside the transport, communications more developed, is attracting more and more attention to the eyes.

RSID Solutions aims to be a world class provider from China on cards manufacturing, application and ID solutions! Working with authorized top-level players, our global network will always be at your tailor-made service before & after sales, V.A.S as well.

Thanks for 15-years’ experience and numerous users’ trust, the most top players in card industry are using the machines & solutions which we highly recommended.

Whatever you are card & RFID manufacturer, personalization center or issuer, you will get reliable services & abundant resources here!

Strong Key Partners

Leading technical provider from China

• Secure ID & E-Passport

• Secure ID & E-Passport• Banking Machine

• E-Payment System

• Rail transit AFC

☆ More than 18 years professional service experience for global customers

Proven By Numerous Users

Professional Team

A Common Goal: To be a world class service provider for card/RFID making machines and ID solutions; to promote & accelerate the influence of machinery & ID Solutions made in China to global Smart Cards and RFID industry.

Abundant skills: Bachelor or above degree, mechanics or trade related major.

Smooth Information Exchange

Spirit & Enthusiasm: experienced young team with passion are ready for any challenge and opportunity. We will reply your inquiry within 24 hours and can afford you consultation for 24 hours of 7 days in the process of sale and after service by phone or mail. We will support you for advisory opinion in purchasing, explanation in various technical problems and reliable supply in technique support.

Values

• Customers are our employers, for whom we solve the problem and create more values abidingly.

• Employees are our best wealth, for whom we continuously widen the development platform and expand the space of survival.

• Partners are our business foundations, for whom we make more opportunities and benefit multi-win persistently.

• Society is our survival land to which we contribute by making efforts to improve day by day, and industry development as well.

Other Advantages

• Adequate Supply

• Attractive Price

• Customized Service

• More Than 10 Oversea Engineers Standby in 7*24 Hours

Europe:

North America:

South America:

Africa:

Oceania:

Special:

Services before Sales

- Reply your inquiry within 24 hours.

- Communication by email.

- Welcome you visiting our factory and final users in China.

- Help for VISA application and Invitation Letter issuing.

- We afford you consultation for 24 hours of 7 days in the process of sale and after service by phone or mail. We will support you for advisory opinion in purchasing, explanation in various technical problems and reliable supply in technique support.

Services on Purchasing

- Communication by email.

- Welcome you visiting our factory and final users in China.

- Help for VISA application and Invitation Letter issuing.

Services after Sales

- Online Support, 24 hours feedback once got the email

- Enough Spare Parts Preparation for you…

- Engineer to customer’s site for training & repairment

- Our equipments have 12 months for quality guarantee after sale. If the equipments do not work because of self cause, we will do free service and change the damaged spare parts.

- We will do life-long maintenance for all of our sold equipments. After quality guarantee period, if you can not maintain the equipments by self, we are under an obligation to go to work place and assist you to make maintenance. The cost of spare parts as well as expenses of traveling and man-hour of worker will be negotiated separately. Spare parts will be supported whether during guarantee period or not.

- After have finished maintenance, our service engineer will do training for the operators in plenty of time so that operators can be ensured to independently make operation, debugging and daily plant maintenance.

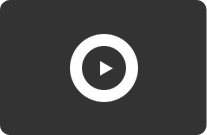

RFID Automatic Flip Chip System XJL-TTA20000

RFID Automatic Flip Chip System XJL-TTA20000

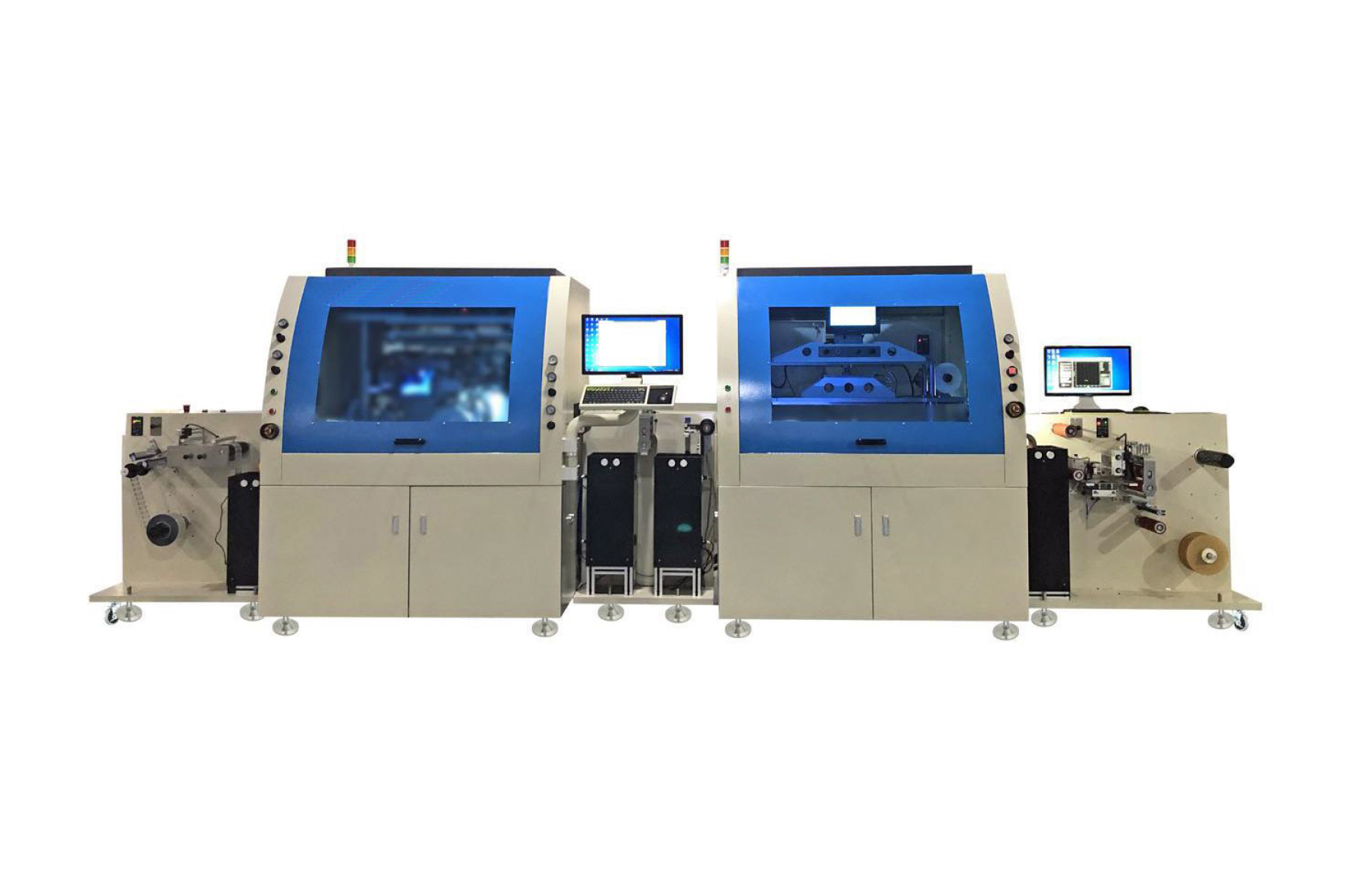

RFID Label Automatic Lamination Machine RFCL-822-RX

RFID Label Automatic Lamination Machine RFCL-822-RX

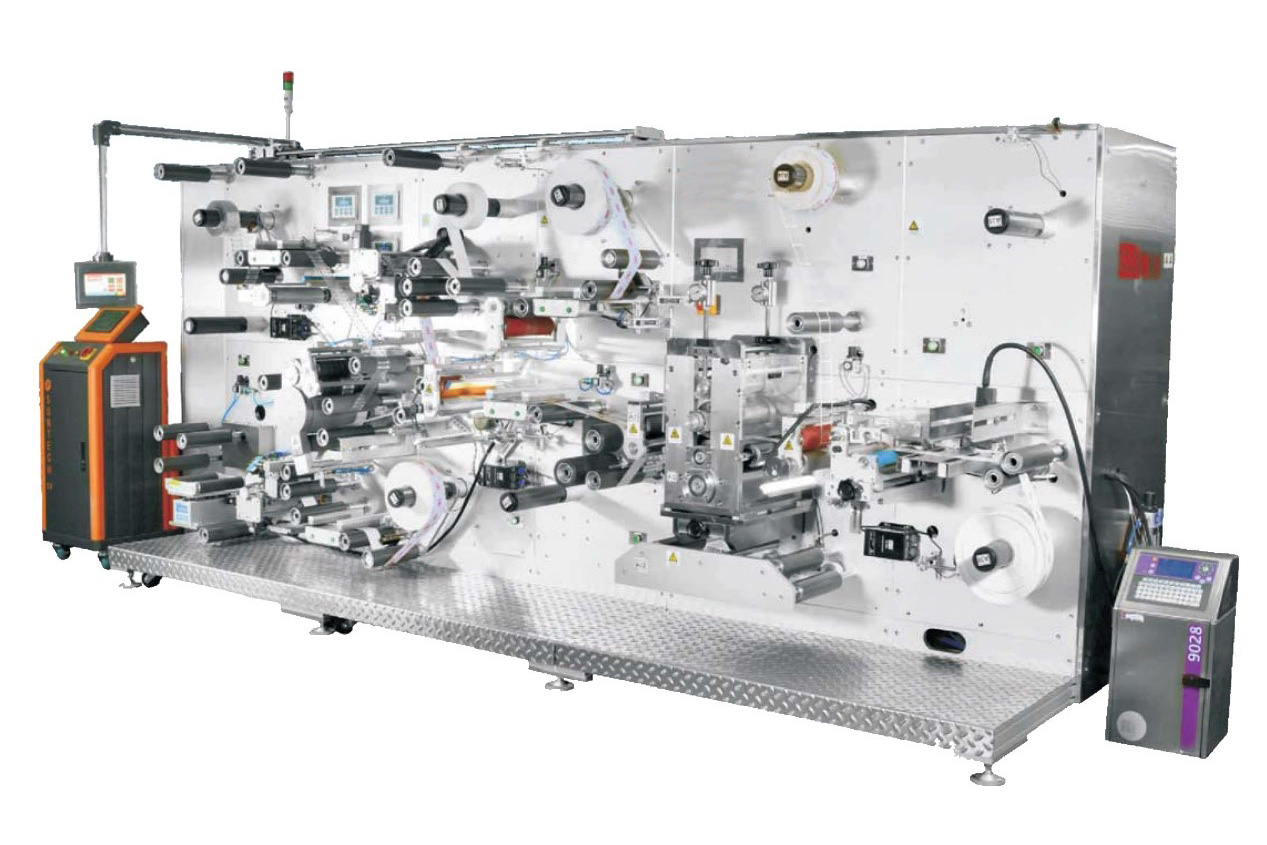

RFID Label Detecting & Encoding Machine RFES-1

RFID Label Detecting & Encoding Machine RFES-1

300/600dpi HD Single Tag Printer

300/600dpi HD Single Tag Printer