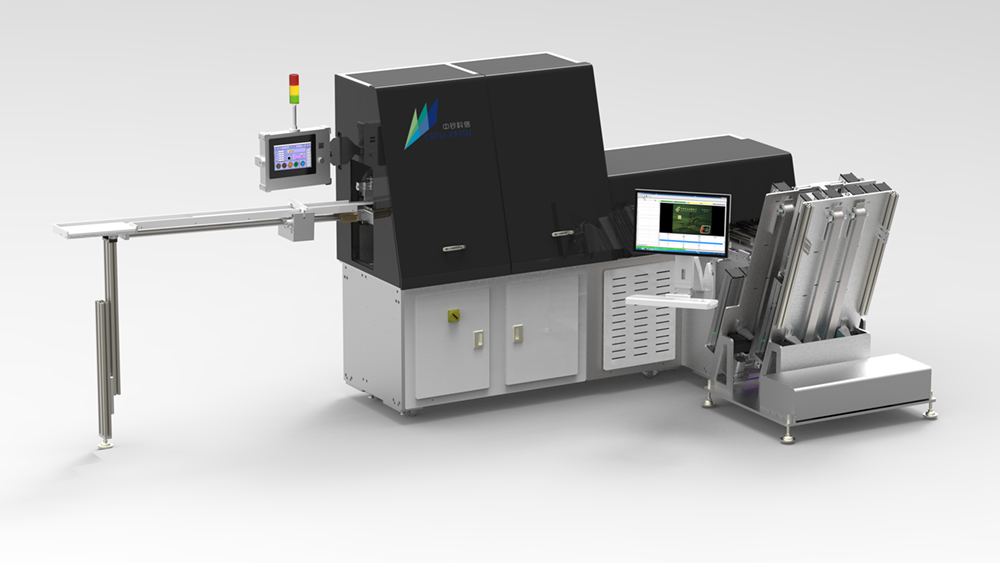

Presentation: Integrated high-tech vision systems and software with rotary design to inspect the card surface quality

Advantage: High speed, accurate, stable and customized. Save manpower cost to do the checking

Application: Banking Card/ SIM Card/Membership Card Manufacture

Brochure Download:Down

- Overview

- Typical Client Needs

- Photo & Video

- Features

- Specification

- Why Buy It

- Reference & Feedback

- Service & Support

- FAQ

- Question & Advice

As 4th generation Auto Card Inspection System, KX-CardCore-V3 is designed to inspect card surface defects, such as dent, spot, bubble, scratch, artwork problem, printing error, holo & S.P incorrect, position/color deviation, etc.

It’s designed by CBPM-KEXIN which is founded by China Banknote Printing and Minting Corporation (CBPM) and China Academy of Sciences (CAS) and Shenzhen Cinda Investment Co., Ltd. They have a lot of innovate IP results in the image processing, precision machinery and optical, electronics and mechanic integration. Especially, the banknote sorting machine & card inspection machine has been widely used for more than 5 years.

APPLICATIONS

• No risk investment will bring you more competition power!

• The Mature Tech: 5 years usage in big banking cards manufacturing

• Smart Card, SIM/GSM Card, Financial Card, ID Card, Membership Card, Gift Card, ISO7810/7816 Card…

WORKFLOW

INSPECTION ITEMS

There are two cameras per inspection stations

• Surface inspection

- Monochrome cameras

- Surface Quality: Scratches, Spot, Bubble, Bulge, Dent, Punching Error, Fiber…

• Visual inspection

- Color cameras

- Printing Quality: Matt, Cross Color, Color Registration, Registration Error, Printing Registration relative to spatial objects, Missing Printing/ Incomplete Text, Ink Spots, Contam, Color Dot, Picking Ink, Oil Stains, UV Spots, OVI, Secured Printing, Water Mark, Subtle Color or Brightness Shifts, Localized Flaw, Any Other Printing Error…

- Card Visual Items: Chip Position, Shape & Position of Logo, S.P, Magnetic Stripe, Hologram, Partial Missing of Lamination Foil, Holes On Lamination Foil…

• UV invisible inspection

- UV camera

- UV invisible

• Hologram's graphic and content inspection(optional)

- Monochrome camera

- Hologram's graphic and content

• Pearly-lustre inspection, Micro-text inspection(optional)

ADVANTAGES

• High Efficiency, Quality & Precision

|

Item |

Manually | KXN00 |

|

Throughput |

2,000UPH |

25,000UPH |

|

Efficiency Ratio |

1 | 12.5 |

|

Benefits |

e.g.13,000 USD per annum per capita. |

8-10 labors down and recover cost in 1-2 years |

• High Added Value:

- Increase output and improve company VI to attract new clients and win bids

- Reduce reject ratio & complain and foster customer loyalty & advocacy

• Innovative Technology:

- None-scratch cards feeding design solutions

- Template setting in 30 mins & 5 mins for repeat job

- Multiple inspection windows to ignore or accent specific areas of card

- Wide card composite and compatible for original production line

- The Best Self-developed Parts in the market: IPC, strobe light source, software…

• Perfect Service:

- 7*24 call on standby service

- Free software & hardware upgrading, spare parts replacement like light source in 1 year Warranty

- Technical Support from China Banknote Printing and Minting Corporation (CBPM) and China Academy of Sciences (CAS)…

TECHNICAL SPEC

|

Max. Output |

• 26,000CPH |

|

Inspection Width |

• 100mm×90mm (Can be designed as actual conditions) |

|

Cards Feeding Capacity |

• 1,000 Cards(1mm thickness) |

|

Min. Inspection Tolerance |

• Dia.: 0.04mm (0.1-0.2mm is popular in real production); △E: 3 |

|

Optical System |

• 2 Million Pixel Greyscale/8 Million Pixel Color Dalsa Cameras |

|

Cards Collection |

• 4 collection magazines, each one can be defined by user. |

|

Optional Parts |

• Industrial Touch PC, MES Upload, Remote Pattern Setting, Remote Wireless Display |

|

Optional Inspection Items |

• UV/Micro text, Format, Content of Labels, 3D Image, Customized Items |

|

Efficiency |

• 100% Unqualified Cards Inspection & 95% Availability |

|

Operator |

• 1 person |

TECHNICAL SPEC

• Ink Spots, Contam, Hicky, Color Dot, Picking Ink • Bubble & Foreign Matt

• Missing Letters/Incomplete Text • Color Registration

• Scratch • Spot UV

• Hot Stamp • Signature Missing or Position Error

• Hologram Position & Defects • Image Position in the card (punching error)

• SIM Card • ID Card

• Color Deviation (background, logo, etc.) • Invisible Ink

Defects can be detected: Surface Scratching, Laminated Watermark, Air Spots, Bubbles, Gas Blots, Punching Errors (Black Edges), Unclear Print, Fringe, Watermarks, etc.

Location of the Card LOGO, Union Pay Sign, VISA Sign, Magnetic Stripe, Signature Panel, etc. And the Detection of the External Dimension.

B. Meet Client’s Requirements.

Traditional card inspection is done by human eyes. So card factory always apply manpower to check the quality of the card surface. There are some disadvantages by using manpower: low speed, high cost, easy tired, quality differs with different persons.

Apply automatic machine to check the quality can ensure high efficient, high accurate and high quality.

SAMPLE REFERENCE

• High Efficiency, Quality & Precision

|

Item |

Manually | KXN00 |

|

Throughput |

2,000UPH |

25,000UPH |

|

Efficiency Ratio |

1 | 12.5 |

|

Benefits |

e.g.13,000 USD per annum per capita. |

8-10 labors down and recover cost in 1-2 years |

• High Added Value:

- Increase output and improve company VI to attract new clients and win bids

- Reduce reject ratio & complain and foster customer loyalty & advocacy

• Innovative Technology:

- None-scratch cards feeding design solutions

- Template setting in 30 mins & 5 mins for repeat job

- Multiple inspection windows to ignore or accent specific areas of card

- Wide card composite and compatible for original production line

- The Best Self-developed Parts in the market: IPC, strobe light source, software…

• Perfect Service:

- 7*24 call on standby service

- Free software & hardware upgrading, spare parts replacement like light source in 1 year Warranty

- Technical Support from China Banknote Printing and Minting Corporation (CBPM) and China Academy of Sciences (CAS)…

|

Max. Output |

• 26,000CPH |

|

Inspection Width |

• 100mm×90mm (Can be designed as actual conditions) |

|

Cards Feeding Capacity |

• 1,000 Cards(1mm thickness) |

|

Min. Inspection Tolerance |

• Dia.: 0.04mm (0.1-0.2mm is popular in real production); △E: 3 |

|

Optical System |

• 2 Million Pixel Greyscale/8 Million Pixel Color Dalsa Cameras |

|

Cards Collection |

• 4 collection magazines, each one can be defined by user. |

|

Optional Parts |

• Industrial Touch PC, MES Upload, Remote Pattern Setting, Remote Wireless Display |

|

Optional Inspection Items |

• UV/Micro text, Format, Content of Labels, 3D Image, Customized Items |

|

Efficiency |

• 100% Unqualified Cards Inspection & 95% Availability |

|

Operator |

• 1 person |

RSID Solutions is a professional machinery & ID solutions provider from Shanghai, a member of RealSmart Group Company founded in 2005. And Shanghai is a dynamic growing prosperity of the city, is China's largest commercial and financial center; is also the Western Pacific region important international port city. Its extensive contacts within and outside the transport, communications more developed, is attracting more and more attention to the eyes.

RSID Solutions aims to be a world class provider from China on cards manufacturing, application and ID solutions! Working with authorized top-level players, our global network will always be at your tailor-made service before & after sales, V.A.S as well.

Thanks for 15-years’ experience and numerous users’ trust, the most top players in card industry are using the machines & solutions which we highly recommended.

Whatever you are card & RFID manufacturer, personalization center or issuer, you will get reliable services & abundant resources here!

Strong Key Partners

Leading technical provider from China

• Secure ID & E-Passport

• Secure ID & E-Passport• Banking Machine

• E-Payment System

• Rail transit AFC

☆ More than 18 years professional service experience for global customers

Proven By Numerous Users

Professional Team

A Common Goal: To be a world class service provider for card/RFID making machines and ID solutions; to promote & accelerate the influence of machinery & ID Solutions made in China to global Smart Cards and RFID industry.

Abundant skills: Bachelor or above degree, mechanics or trade related major.

Smooth Information Exchange

Spirit & Enthusiasm: experienced young team with passion are ready for any challenge and opportunity. We will reply your inquiry within 24 hours and can afford you consultation for 24 hours of 7 days in the process of sale and after service by phone or mail. We will support you for advisory opinion in purchasing, explanation in various technical problems and reliable supply in technique support.

Values

• Customers are our employers, for whom we solve the problem and create more values abidingly.

• Employees are our best wealth, for whom we continuously widen the development platform and expand the space of survival.

• Partners are our business foundations, for whom we make more opportunities and benefit multi-win persistently.

• Society is our survival land to which we contribute by making efforts to improve day by day, and industry development as well.

Other Advantages

• Adequate Supply

• Attractive Price

• Customized Service

• More Than 10 Oversea Engineers Standby in 7*24 Hours

Services before Sales

- Reply your inquiry within 24 hours.

- Communication by email.

- Welcome you visiting our factory and final users in China.

- Help for VISA application and Invitation Letter issuing.

- We afford you consultation for 24 hours of 7 days in the process of sale and after service by phone or mail. We will support you for advisory opinion in purchasing, explanation in various technical problems and reliable supply in technique support.

Services on Purchasing

- Communication by email.

- Welcome you visiting our factory and final users in China.

- Help for VISA application and Invitation Letter issuing.

Services after Sales

- Online Support, 24 hours feedback once got the email

- Enough Spare Parts Preparation for you…

- Engineer to customer’s site for training & repairment

- Our equipments have 12 months for quality guarantee after sale. If the equipments do not work because of self cause, we will do free service and change the damaged spare parts.

- We will do life-long maintenance for all of our sold equipments. After quality guarantee period, if you can not maintain the equipments by self, we are under an obligation to go to work place and assist you to make maintenance. The cost of spare parts as well as expenses of traveling and man-hour of worker will be negotiated separately. Spare parts will be supported whether during guarantee period or not.

- After have finished maintenance, our service engineer will do training for the operators in plenty of time so that operators can be ensured to independently make operation, debugging and daily plant maintenance.

Card Surface Inspection System KX-CardCore-V3

Card Surface Inspection System KX-CardCore-V3