- Overview

- Typical Client Needs

- Photo & Video

- Features

- Specification

- Why Buy It

- Reference & Feedback

- Service & Support

- FAQ

- Question & Advice

OVERVIEW

Milling bit is one of the most important tools and consumables in the smart card production. Ordinary milling bits are directly processed from tungsten steel, so the lifespan is short and easy to scratch winding wires for dual interface cards. Through the development and validation of the milling bit, RSID Solutions optimize blade structure and material to make it in longer extending life and higher quality consistency.

If you want a batch of endmill bits with not only extended life, but also stable life and high cost-effective performance, we are willing to work with you to achieve this target.

APPLICATIONS

• It is suitable for milling the chip cavity likes M2, M3, M5 of various contact smart cards (SIM Card, Dual Interface Card, etc.)

• Support different card material (PVC , PET, ABS, PET-G, etc.)

• It also has superior performance for the processing of metal cards, such as copper, aluminum and stainless steel.

FEATURES

• Adopts standardized diameter of the handle, easy to install on various high-speed spindles.

• Adopts special high-precision automatic CNC machining which can adjust any angle and ensure consistency.

• Using PCD or MCD as the blade, it is 10 times the life of ordinary tungsten steel. From a great deal of experience, PCD bits are machined in Sim cards up to 200,000 cavities/bit.

• Welded handle can be recycled.

• Double blades are available as well.

• Great ratio of cost & performance.

SPECIFICATIONS

LIFESPAN

PACK

• Packaging process

• Packaging Parameter

Pack 1 bit/ plastic box, Total weigh: 10g;

Pack 165 bits/ carton ,Total weigh:1.75kg;

Carton size:200X150X80(mm)

Milling bit is one of the most important tools and consumables in the smart card production. Ordinary milling bits are directly processed from tungsten steel, so the lifespan is short and easy to scratch winding wires for dual interface cards. Through the development and validation of the milling bit, RSID Solutions optimize blade structure and material to make it in longer extending life and higher quality consistency.

If you want a batch of endmill bits with not only extended life, but also stable life and high cost-effective performance, we are willing to work with you to achieve this target.

APPLICATIONS

• It is suitable for milling the chip cavity likes M2, M3, M5 of various contact smart cards (SIM Card, Dual Interface Card, etc.)

• Support different card material (PVC , PET, ABS, PET-G, etc.)

• It also has superior performance for the processing of metal cards, such as copper, aluminum and stainless steel.

FEATURES

• Adopts standardized diameter of the handle, easy to install on various high-speed spindles.

• Adopts special high-precision automatic CNC machining which can adjust any angle and ensure consistency.

• Using PCD or MCD as the blade, it is 10 times the life of ordinary tungsten steel. From a great deal of experience, PCD bits are machined in Sim cards up to 200,000 cavities/bit.

• Welded handle can be recycled.

• Double blades are available as well.

• Great ratio of cost & performance.

SPECIFICATIONS

LIFESPAN

PACK

• Packaging process

• Packaging Parameter

Pack 1 bit/ plastic box, Total weigh: 10g;

Pack 165 bits/ carton ,Total weigh:1.75kg;

Carton size:200X150X80(mm)

• Adopts standardized diameter of the handle, easy to install on various high-speed spindles.

• Adopts special high-precision automatic CNC machining which can adjust any angle and ensure consistency.

• Using PCD or MCD as the blade, it is 10 times the life of ordinary tungsten steel. From a great deal of experience, PCD bits are machined in Sim cards up to 200,000 cavities/bit.

• Welded handle can be recycled.

• Double blades are available as well.

• Great ratio of cost & performance.

• Adopts special high-precision automatic CNC machining which can adjust any angle and ensure consistency.

• Using PCD or MCD as the blade, it is 10 times the life of ordinary tungsten steel. From a great deal of experience, PCD bits are machined in Sim cards up to 200,000 cavities/bit.

• Welded handle can be recycled.

• Double blades are available as well.

• Great ratio of cost & performance.

Those Might Attract You

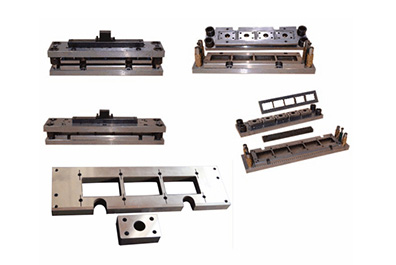

Die & Tooling

Die & Tooling

Long service life

Size is available to be customized

Apply to PVC, ABS, PET and PC cards

Use at most of the punching machines

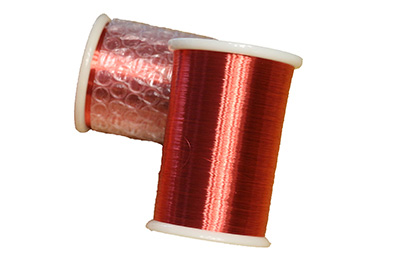

Enamelled Copper Wire

Enamelled Copper Wire

Good embedded ability

Match various coil manufacturing tech

Apply to L.F, H.F Inlay manufacturing

Apply to RFID card/tag manufacturing

High-temperature Resistance Cloth

High-temperature Resistance Cloth

Good pressurization

Reduced chip loss rate

Perfect heating conduction

Specially for RFID Inlay/Pre-laminated production

Lamination Plate

Lamination Plate

Better card surface quality

Glossy & matte types, customized size

Good thermal conductivity and pressurization

Commonly used in smart card manufacturing

products